Chamfering is used primarily in the forging markets. Putting a chamfer on the ends of the forged rod can prevent stress cracks during the forging process. IMC can chamfer rods from 2″- 8″ in diameter. Our standard chamfer radius is .500, but can be adjusted as needed. Larger parts chamfering is performed manually with a grinding disc on a rotating turning center.

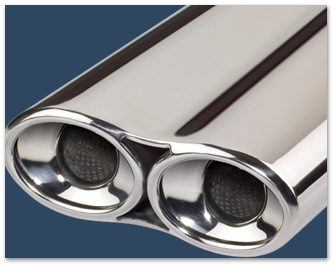

Electropolishing utilizes electrical current and chemicals in an electrolytic bath to remove burrs and produce a high luster finish. This process provides a stress-free polishing method that preserves the surface finish, improves the fatigue life of the part, removes contaminants, passivates, and creates a surface that retards corrosion.

Electropolishing flattens the surface, removes burrs, weld marks, scale from heat treating, and produces a flawless, mirror-like surface. Finishes can be improved as much as 50% RA, or down to an RA of 2, depending on the part. Electropolishing is ideal to reach interior surfaces where other polishing methods cannot. Also, Electropolishing provides a surface that will remain glossy and polished for a much longer period of time than standard mechanical polishing.

Electropolishing has become the preferred method for metal finishing in a variety of industries such as Medical, Pharmaceutical, Biotechnology, Food Processing, Water Treatment, Automotive, Marine, Aeronautics, and Electronics.

If you are considering electropolishing for your stainless steel products or parts, IMC has a special offer for you – we’ll electropolish any one part for FREE!* All you do is simply send us any one part or product and we’ll return it fully electropolished with a price quote and delivery lead time.

* Shipping and handling not included